Products

Heavy duty grantry machining center

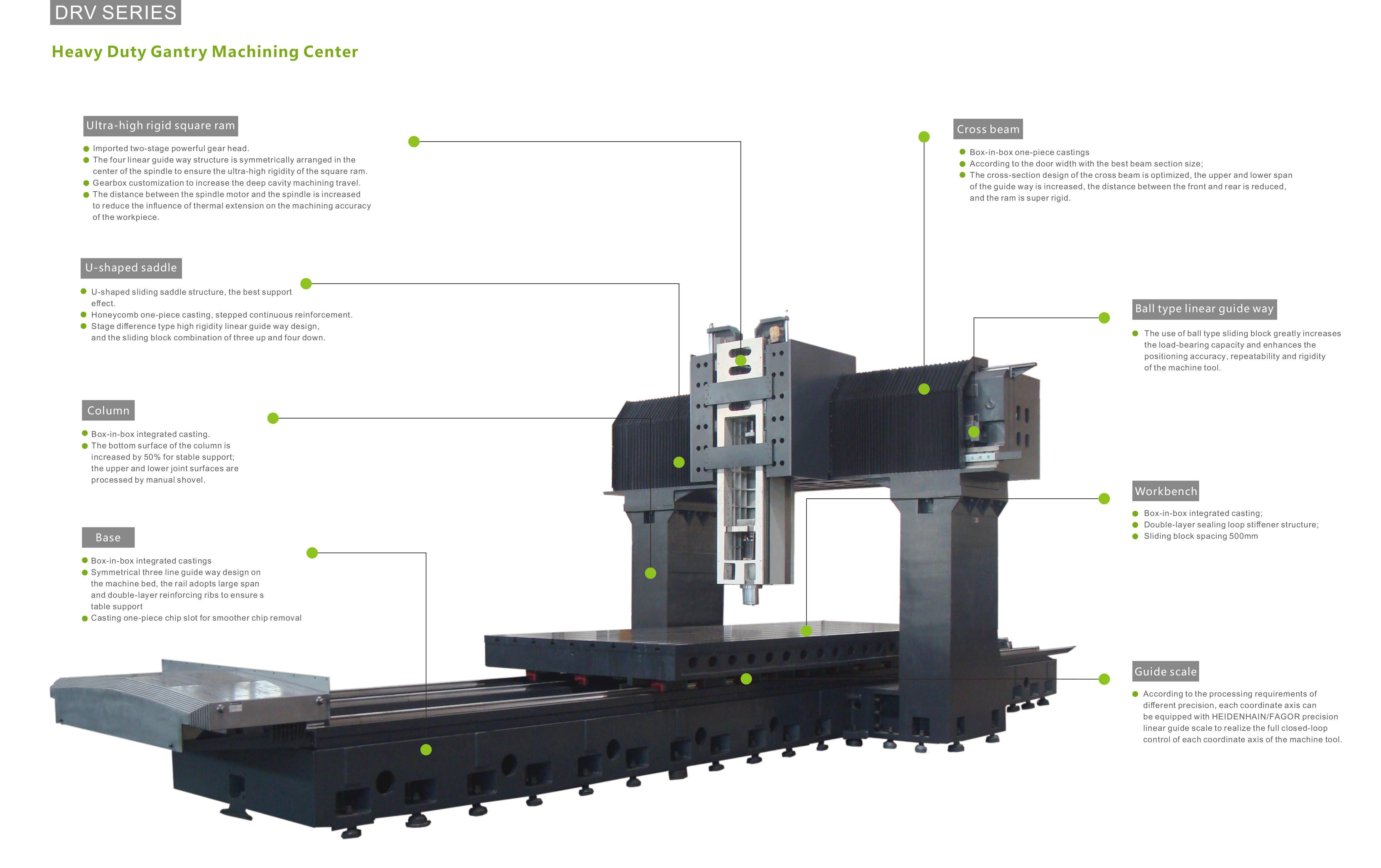

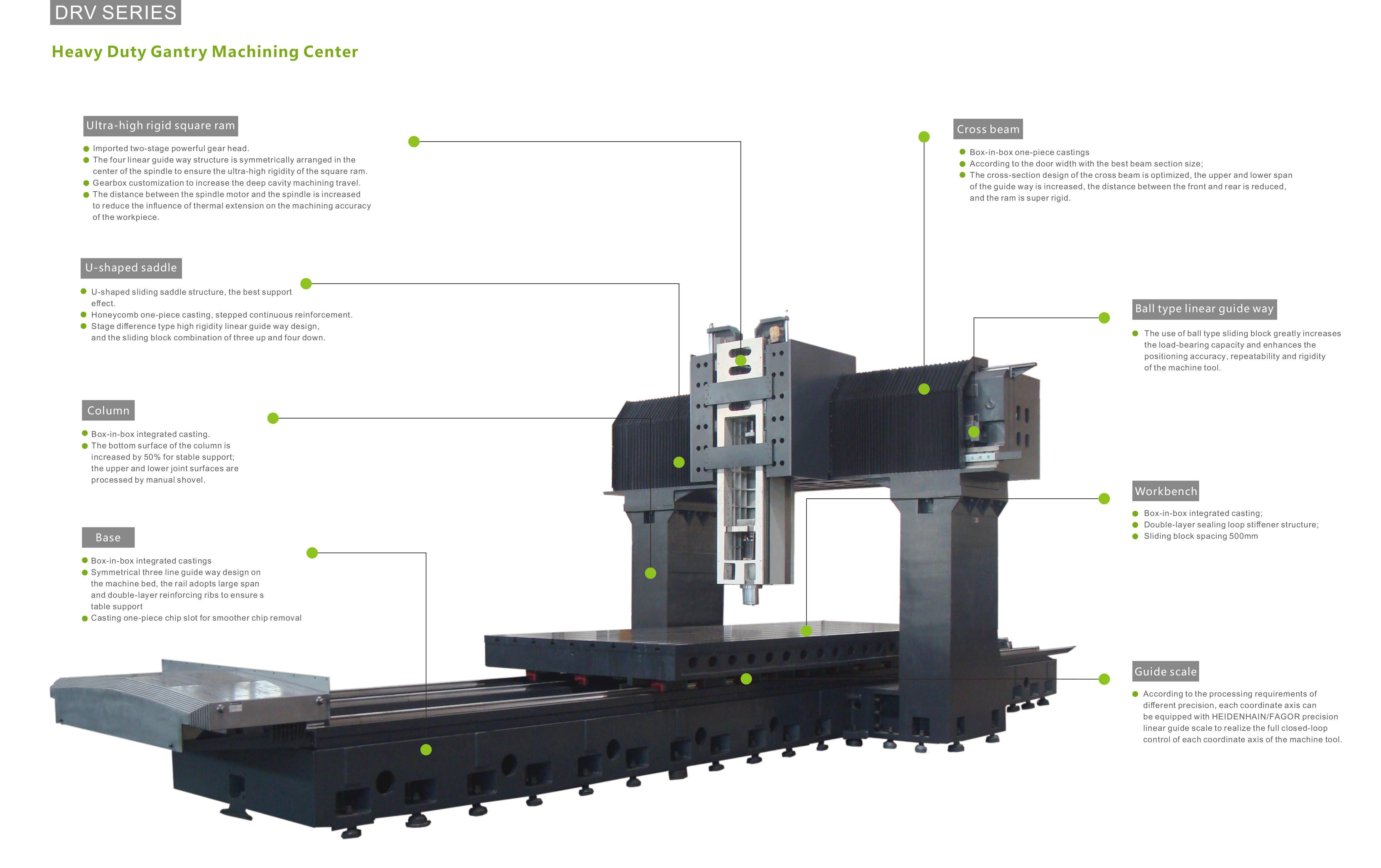

The gantry style symmetrical structure adopts a box in box integrated casting for the body, and the column is increased by 50% compared to the industry, making the body more stable. It has high thermal symmetry, high rigidity of the entire machine, and co

Product Features

The gantry style symmetrical structure adopts a box in box integrated casting for the body, and the column is increased by 50% compared to the industry, making the body more stable. It has high thermal symmetry, high rigidity of the entire machine, and comprehensive performance of high rigidity heavy-duty cutting and high-precision machining. The main accessories such as screw rods, screws, and servo motors are all from well-known imported brands, ensuring the stability of the machine tool.

The Z-axis adopts dual counterweight oil cylinders, which can eliminate the generation of unbalanced torque. The spindle center is symmetrically arranged with a four track structure, and each track is distributed with three sliders to ensure the smoothness of high-speed feed and long-term machining accuracy of the Z-axis.

The imported two-stage strong gear head transmission increases torque and exhibits stronger heavy cutting ability.

Top mounted gearbox, increasing deep cavity machining stroke, reducing spindle thermal extension, ensuring machining accuracy and heavy cutting ability. Integrated chip removal groove for castings ensures smooth chip removal and effectively saves processing space.

The fully automatic head compartment system is equipped with various types of additional milling heads to improve the machining efficiency of the machine tool and achieve easy tool changing. At the same time, it can provide automatic pentahedral and vertical horizontal dual output pentahedral models to meet various machining needs of customers.

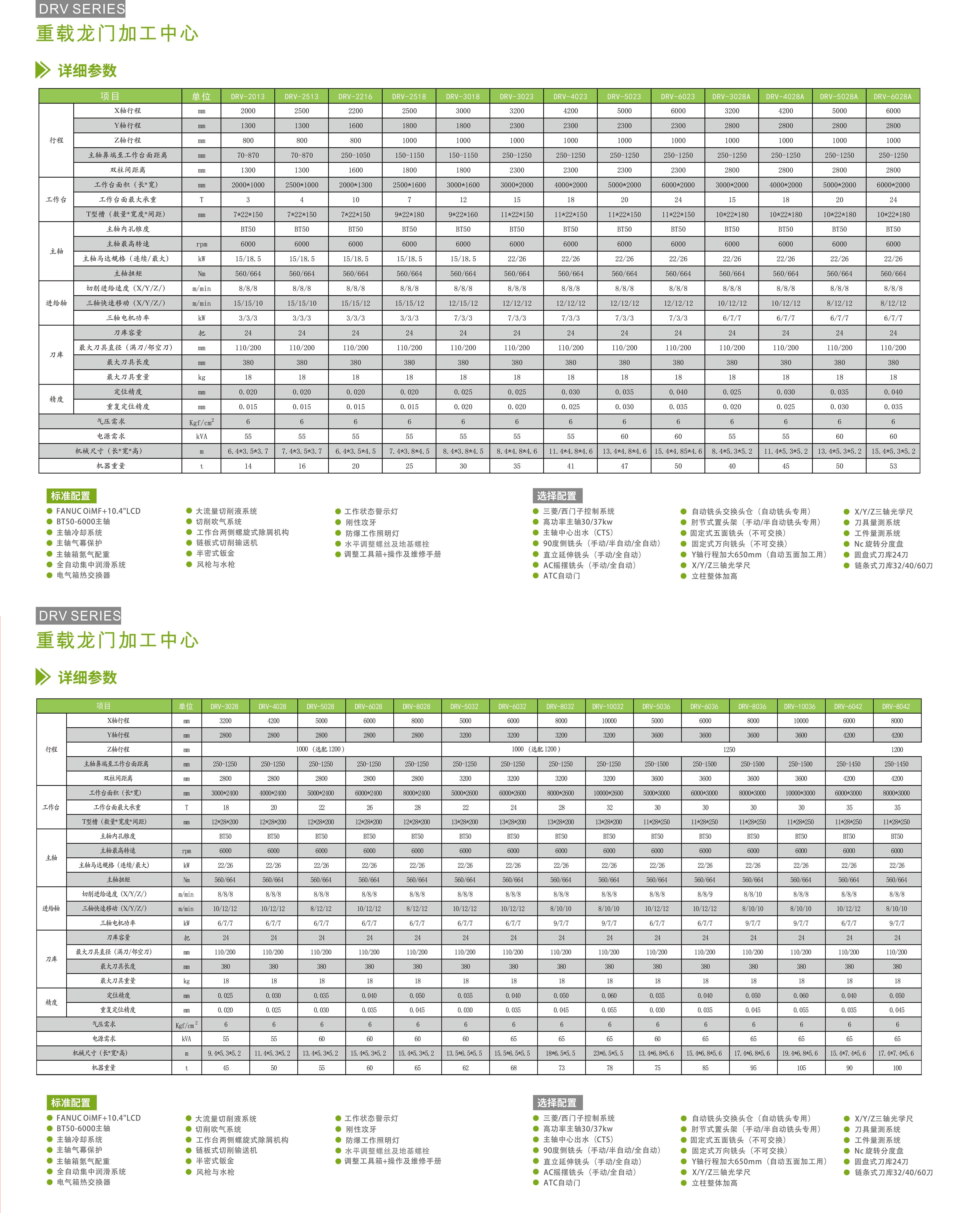

Technical Parameter